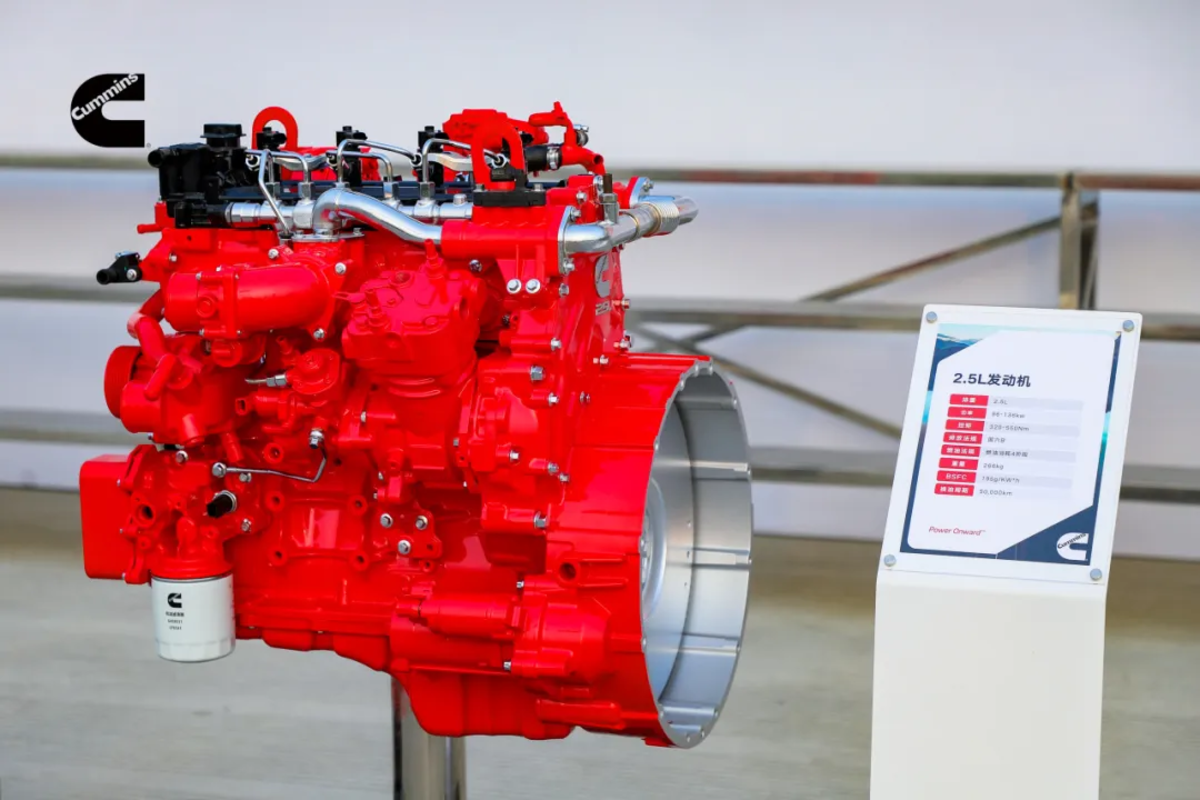

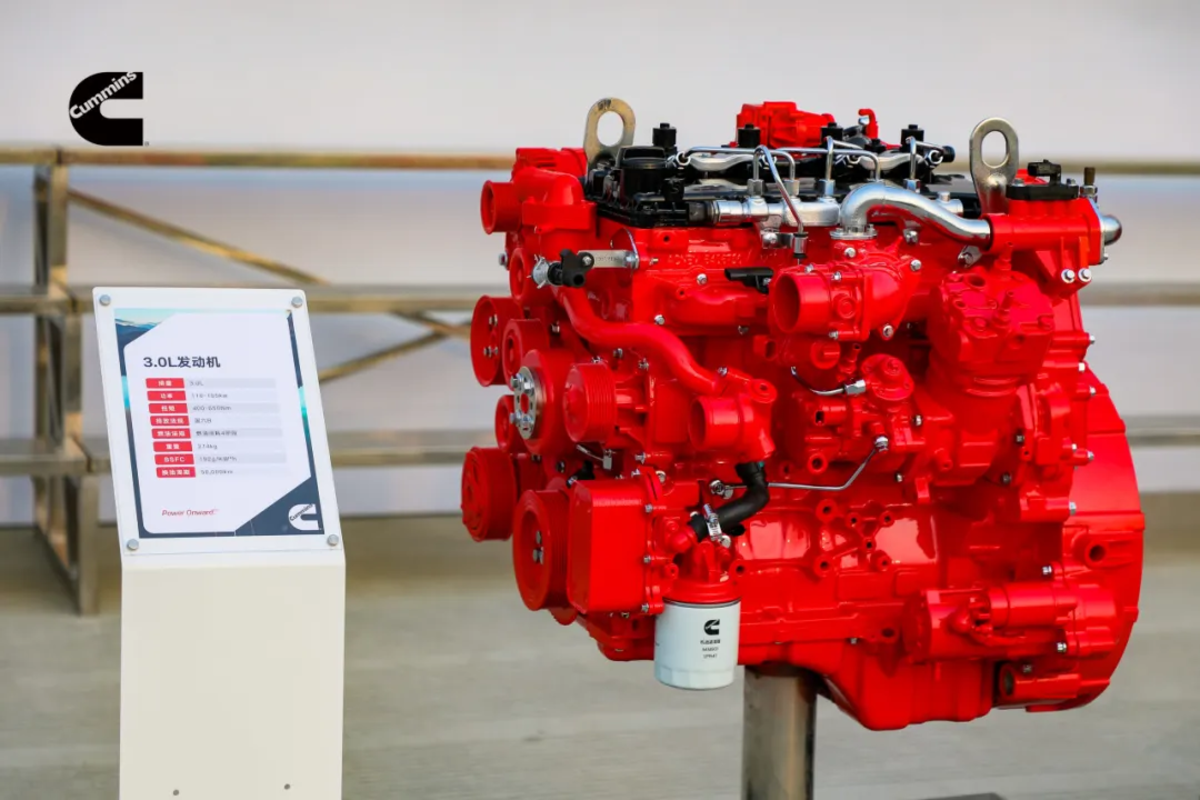

On November 5, 2024, Cummins China, in collaboration with its joint ventures Dongfeng Cummins, Foton Cummins, and Anhui Cummins, officially launched the new generation 2.5L and 3.0L light-duty engine platform at the Cummins East Asia R&D Center. The new generation of light-duty diesel engine platform meets China’s National VI B emission standards and Stage IV fuel consumption regulations, while significantly enhancing reliability, fuel efficiency, and power. Following the pioneering launch of the National VI standard light-duty platform in 2019, Cummins continues to innovate, leading the way in light-duty truck power upgrades and offering new choices to meet diverse customer needs.

Li Kaiguo, the former Chairman of China Automotive Engineering Research Institute Co., Ltd. and Supervisor of the China Society of Automotive Engineers, along with representatives from leading domestic light truck logistics fleets, industry media, and the Cummins China and joint venture teams, witnessed this important moment.

As a working tool, the practical application scenarios of light trucks are diverse, and a single solution cannot meet all the demands. In certain specific scenarios and applications, diesel power is not restricted by terrain, weather, or infrastructure, allowing for round-the-clock, uninterrupted use. Moreover, in fields with higher requirements for power and reliability, especially in scenarios such as frequent starts, acceleration, heavy-load climbing, and cold chain transportation that combines both driving and refrigeration needs, diesel-powered light trucks currently have a relative advantage.

Against this backdrop, Cummins remains committed to innovation and breakthroughs in the traditional energy power sector. In collaboration with its three joint ventures, Cummins has developed a new generation light-duty power platform that meets Stage IV fuel consumption standards, offering light truck users a low-carbon, efficient power solution.

Guided by the zero-carbon goal, Cummins, based on its locally rooted FFA2.0 (Customized Applications) strategy and deep market insights, has collaborated with its three major domestic OEM partners for joint innovation. Leveraging the solid manufacturing foundation of its joint ventures and the unique technological legacy of Cummins’ century-old diesel power expertise, the company has launched the new generation 2.5L and 3.0L light-duty engine platform after three years of meticulous research and development. This platform incorporates the intelligent “brain” (CBM2.0) technology, achieving an excellent balance of fuel consumption, reliability, durability, economy, and performance, providing users with a more efficient and long-lasting power experience.

The new generation engine platform from Cummins offers comprehensive improvements in reliability, economy, and performance.

Reliability:

- Underwent 25,000 hours of bench testing and over 3 million kilometers of on-road vehicle testing.

- Multiple rounds of rigorous testing under extreme conditions, including high temperatures, high altitudes, and low temperatures.

- Verified through a total of 1,200 hours of high-pressure endurance testing.

Economy:

- Fuel consumption is reduced by 8% at the engine level, with overall vehicle fuel efficiency optimization reaching up to 15%.

- The intelligent “brain” (CBM2.0) technology, combined with the IAT intake throttle valve design, precisely controls fuel consumption and improves fuel economy.

- Exceptional low-speed torque delivers higher low-speed horsepower, 11% (2.5L) to 18% (3.0L) higher than competitors in the same class.

- In-cylinder peak pressure is increased from 165 bar to 200 bar, improving pressure endurance.

- Weighing between 266kg and 274kg, the engine features a leading lightweight design that delivers better fuel economy while maintaining comparable power performance.

Performance:

- Lightweight with high power and torque, significantly improving performance (2.5L @ 136 kW, a 22% increase; 3.0L @ 155 kW, a 44% increase).

- Wide peak torque range (1200 rpm – 2900 rpm).

- Significantly improved transient response, providing stronger starting and overtaking power.

- Optimized vehicle powertrain for quick starts, rapid acceleration, and strong hill-climbing ability, enabling high-efficiency transportation.